Why does rubber undergo significant changes in its properties after vulcanization

Release Date:2024-01-20 Click:1611

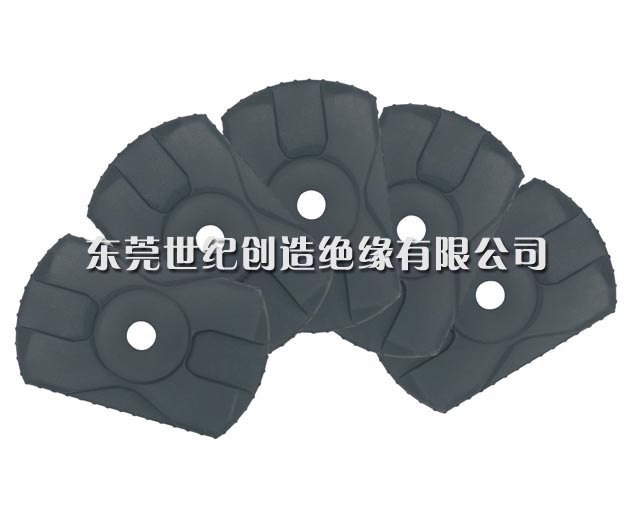

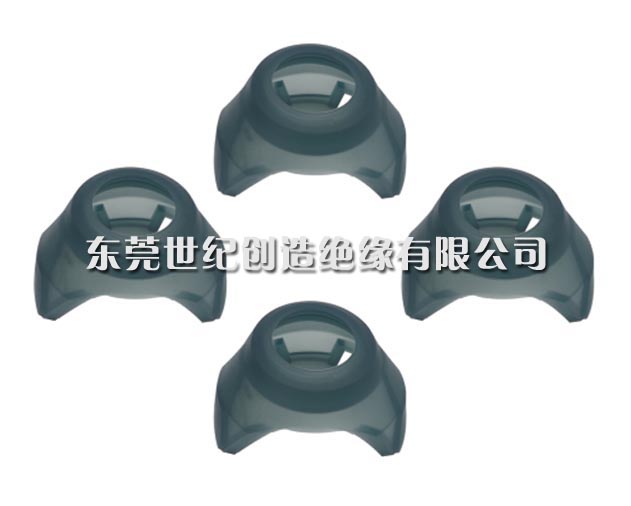

The principle of rubber vulcanization and the advantages of microwave rubber vulcanization. Raw rubber becomes soft when heated, becomes hard and brittle when cooled, is not easy to form, is prone to wear and tear, is easily soluble in organic solvents such as gasoline, has double bonds in the molecules, is prone to addition reactions, and is prone to aging. In order to improve the performance of rubber products, a series of processing processes need to be carried out on raw rubber in production. Under certain conditions, the raw rubber in the rubber material undergoes a chemical reaction with the vulcanizing agent, Crosslinking it from linear macromolecules to three-dimensional network macromolecules, resulting in the rubber material having excellent properties such as high strength, high elasticity, high wear resistance, corrosion resistance, etc. This process is called rubber vulcanization. Generally, the vulcanization process is divided into four stages: induction - pre vulcanization - normal vulcanization - supersulfurization. To achieve this reaction, additional energy must be applied to reach a certain vulcanization temperature, Then let the rubber insulation complete all vulcanization reactions within the vulcanization temperature range

Rubber vulcanization can be achieved through various methods. Traditional methods involve using steam or far-infrared heating to vulcanize the rubber material. However, due to the fact that the heating temperature is slowly conducted from the outside of the medium to the inside, rubber material is a poor thermal conductivity material. For rubber, heating relies on the surface of the material facing the inner layer, and its heat transfer rate is very slow. Most of the time is spent on reaching the vulcanization temperature of the rubber. Therefore, heating time is long and efficiency is low The uniformity of vulcanization is not good, especially when the old process uses magnesium silicate (talc powder) to eliminate rubber adhesion, which causes dust to diffuse in the rubber production workshop, and the dust content in the air far exceeds the standards set by the national environmental protection department. Moreover, the overall vulcanization state of rubber is not ideal. This is because under normal heat conduction conditions, the time for the surface temperature of the vulcanized rubber to rise and the time for the inner layer are not consistent, The phenomenon of uneven vulcanization occurs. Microwave heating is completely different from traditional heating methods, which directly penetrates microwave energy into the heated medium for overall heating. Therefore, heating is fast, efficient, and energy-saving, greatly shortening the rubber vulcanization time, making it more uniform in heating and higher in vulcanization quality. It can cross the induction stage of rubber adhesion and enter the pre vulcanization stage in a short time, The use of talcum powder in the old production process has been eliminated, meeting environmental protection requirements. This production process can concentrate most production processes on one production line, with high automation, low energy consumption, saving manpower, stable production, and uniform product quality, greatly improving production labor conditions

Related news:

- Introduction to Rubber Sponge

- The main factors affecting the vulcanization process of rubber

- The principle of rubber foaming and how it is used for listening to voice during mixing in an internal mixer

- How to distinguish the quality of rubber foam strips?

- How rubber foam strips have a shock-absorbing effect

- Selection of Rubber Raw Materials for Rubber Sponge Products

- Why do we need to undergo secondary rubber vulcanization?

- What are the high-temperature resistance characteristics of rubber sponge materials reflected in?

- Common processing methods for sponge rubber foaming

- Why does rubber undergo significant changes in its properties after vulcanization