Selection of Rubber Raw Materials for Rubber Sponge Products

Release Date:2024-01-20 Click:2025

Rubber sponge products have low density, good elasticity, and good softness and cushioning during use. They have significant thermal and sound insulation effects and a wide range of applications. In actual production, rubber sponge products used in different usage scenarios have different rubber varieties and manufacturing costs. Sponge rubber production enterprises need to choose suitable rubber varieties based on actual needs, and comprehensively consider various factors such as performance and cost. Next, let's talk about the selection of rubber raw materials for rubber sponge products.

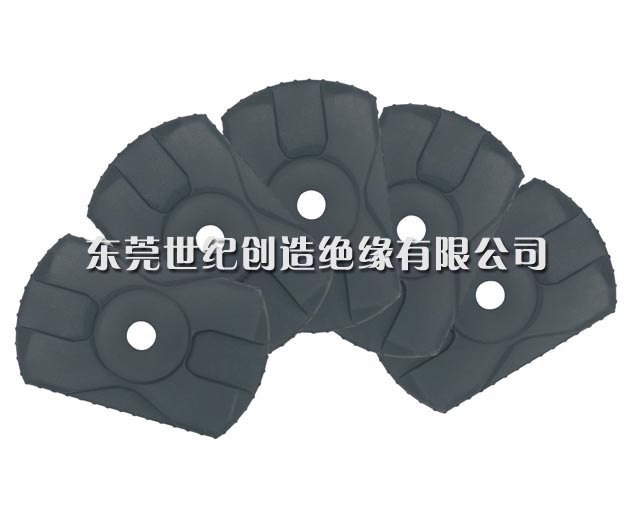

1、 Ordinary sponge products

In actual production, ordinary sponge products do not have special requirements for the aging resistance, ozone resistance, and oil resistance of the rubber used, and generally use natural rubber. To further reduce the raw material cost of sponge rubber HYL12Y1Y2Y products, rubber product manufacturers can use recycled rubber in the formula in moderation, such as tire recycled rubber; High quality natural rubber sponge products can be produced using latex recycled rubber, environmentally friendly tire recycled rubber, tread recycled rubber and other recycled rubber products with higher physical properties.

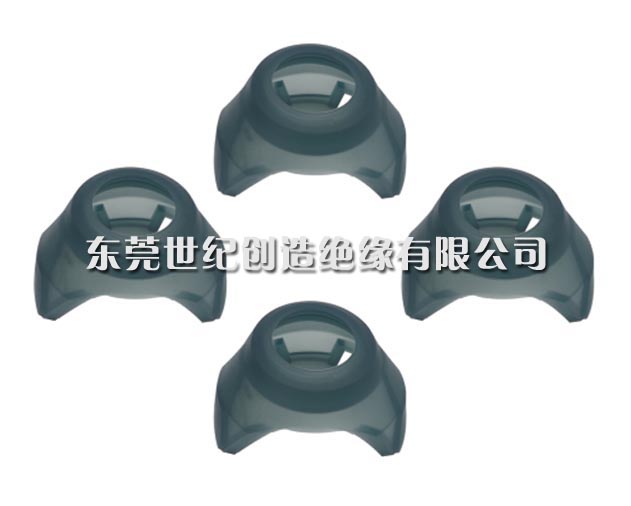

2、 Special performance sponge products

When preparing rubber sponge products with special performance requirements, it is necessary to use special synthetic rubber or special recycled rubber. For example, preparing oil resistant rubber sponge products can use nitrile rubber, nitrile recycled rubber, chloroprene rubber, nitrile rubber/polyvinyl chloride, epoxidized natural rubber, etc. When sponge products require heat resistance and ozone aging resistance, EPDM rubber, EPDM recycled rubber, or special silicone rubber can be used. In actual production, more enterprises tend to use special synthetic rubber in combination with corresponding recycled rubber.

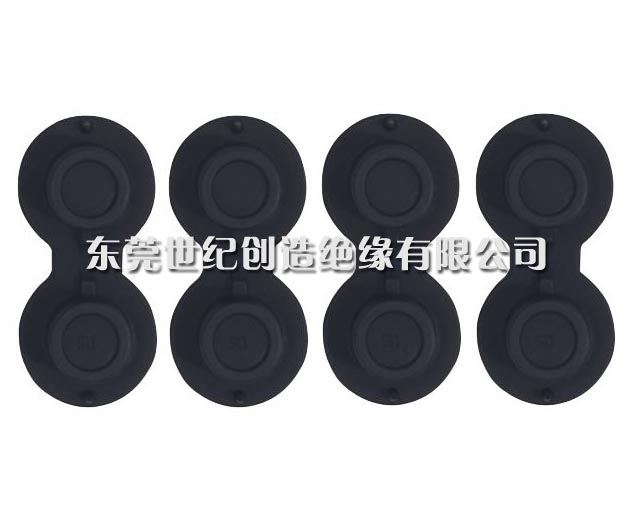

3、 Microporous sponge sole

Microporous sponge shoe soles belong to a special type of rubber sponge products, which can be prepared using a combination of universal rubber/high styrene materials in actual production, or using EVA materials alone. Taking into account the service life, process, cost, and other factors of the micro porous sole, choose a suitable polymer.

Next article:Why do we need to undergo secondary rubber vulcanization?

Related news:

- Introduction to Rubber Sponge

- The main factors affecting the vulcanization process of rubber

- The principle of rubber foaming and how it is used for listening to voice during mixing in an internal mixer

- How to distinguish the quality of rubber foam strips?

- How rubber foam strips have a shock-absorbing effect

- Selection of Rubber Raw Materials for Rubber Sponge Products

- Why do we need to undergo secondary rubber vulcanization?

- What are the high-temperature resistance characteristics of rubber sponge materials reflected in?

- Common processing methods for sponge rubber foaming

- Why does rubber undergo significant changes in its properties after vulcanization